Only high-quality, high-efficiency management can produce satisfactory products. Intelligent control has come, and the transition to a digital factory is the future trend. The company introduced the "MES system" last year to comprehensively manage the workshop.

Establishing a scientific and practical production management system, standardizing work responsibilities and specific work processes have become the key to solving the above chaos. After the introduction of the MES system, our above phenomena have been improved.

Auxiliary scheduling

Through our production scheduling system, we can accurately evaluate the production capacity, accurately reply to the delivery date, and flexibly deal with the adjustment of order insertion plan. This provides great convenience for the sales to receive orders and reply the delivery date to customers. Just check the production scheduling system, we can plan the correct delivery date and leave enough time for other departments in the early stage, such as the conversation and cooperation between the sales department and customers and the time for the design department to issue drawings, one by one, so as to promote the smooth progress of production.

Productivity

In terms of efficiency, although the equipment tact is fixed, it is possible to increase the utilization rate by monitoring the status of the equipment; various shutdowns and wastes in the production process can be accurately recorded by the system and the responsible person, and the production efficiency can be improved through improvement; The upper production schedule is reasonable, reducing the replacement of offline machines, avoiding production congestion, and also improving production efficiency.

At the same time, labor costs can also be reasonably controlled. Through the MES system, the labor hours of workers can be calculated reasonably in order to calculate costs, so as to provide customers with a more cost-effective product solution, win more orders for the company, and save more for customers, to achieve a win-win situation.

Quality traceability

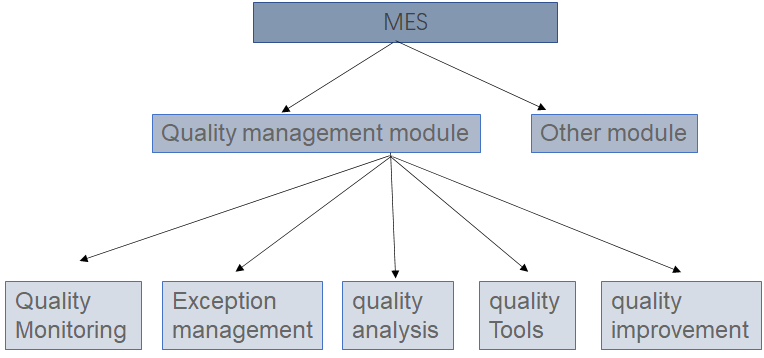

Provide online quality control traceability and other functions to improve our quality management level; we are organically connected to monitor the full-time status of the equipment, and at the same time, the machine parameters can be photographed and uploaded during reporting to provide a basis for future quality traceability.

Through the above operations, the quality of the products can be guaranteed, provide our customers with stable quality products, reduce the chance of rework, let customers trust our products, and make our products become the best products in the industry.

Post time: Feb-23-2022